ALMI Technology - Airborne Laser Scanning

ALMI Technology - Airborne Laser Scanning and Monitoring Integration

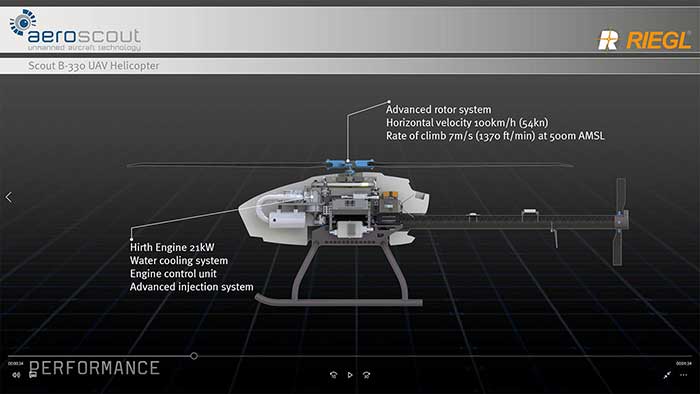

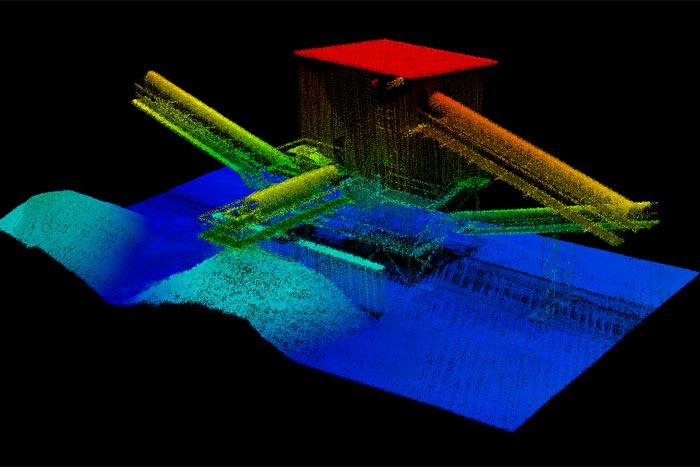

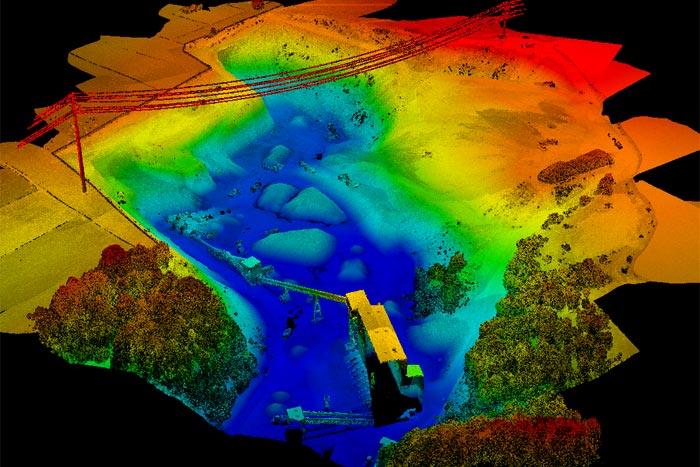

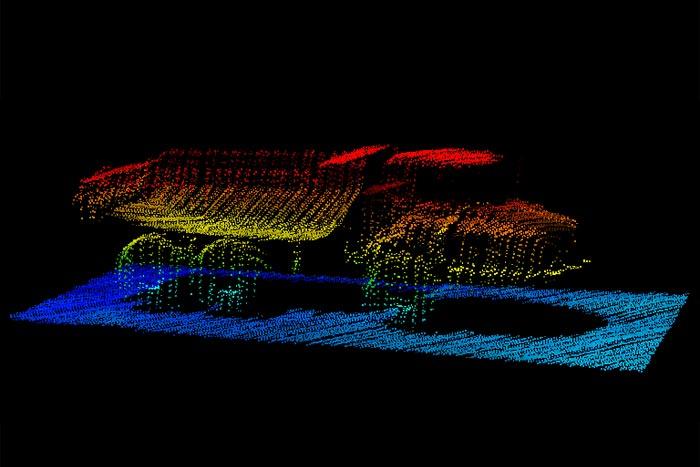

The ALMI technology has been developed by Aeroscout GmbH for professional 3D airborne laser scanning (lidar) based on an unmanned aerial vehicle (UAV). It allows continuously monitored, accuracy controlled, vibration-isolated, and time-synchronized airborne laser scanning from the UAV system. The quality of the laser scans performed with ALMI were proved several times in different case studies (latest here). Aeroscout knows that most likely, the data quality cannot be achieved with competitor equipment.

The ALMI technology has been developed, tested, and successfully demonstrated on the Aeroscout Scout B1-100 UAV helicopter. However, the ALMI technology can also be applied on other UAV systems.

The UAV payload section includes the laser scanner tightly coupled with a high-grade dual-GPS antenna INS/GPS navigation system as well as an GPS reference station.

Aeroscout started developing the ALMI technology as a contributor of the EU research project “BACS” at ETH Zurich (2006-2010). In the last years, the knowledge was transferred into hard- and software for the industrial requirements of airborne laser scanning.

The ALMI technology will allow to perform successful airborne lidar based on the Scout B1-100 UAV helicopter.

Facts of the ALMI Technology

The ground control station can remotely communicate with all payload components to configure them before the flight.

The scanner can be started and stopped remotely from the ground control station (GCS) during the mission flight.

Status information of the laser scanner and the INS/GPS is sent to the ground control station to monitor the ongoing data acquisition during the flight.

The hardware integration of the payload includes an advanced vibration damping to protect the sensitive parts from vibration caused by the engine and the rotors of the UAV system.

The ALMI technology offers various kind of data interfaces such as Ethernet, USB, RS232, RS485, etc. The remote download of recorded 3D laser data and navigation data allows immediate performance control and feedback on the field.

Features of the ALMI Technology

The ALMI technology

- ... can be combined with all state-of-the-art RIEGL laser scanner.

- ... has been optimized for the OXTS INS/GPS navigation unit

- ... allows to integrate a differential GPS reference station providing differential corrections.

- ... can be upgraded to store the differential GPS correction data on ground.

- ... provides online status information of the scanner and the INS/GPS system.

- ... provides online feedback for the recorded data

- ... allows remote access on the recorded data

- ... can be upgraded with a digital photo camera for point cloud photo overlay.

Typical Scenario

The typical scenario of a mission flight depends on the application. The following table shows three different scenarios of different size. The endurance of the Scout B1-100 UAV helicopter is 90 minutes. The scan flight is 60 minutes which allows enough safety margin for starting, flying to the starting point, return, and landing the UAV. A point density of up to 300 points per square meter (28 points per square foot) is an excellent value compared to manned airborne laser scanning with a traditional airplane which typically has 3-5 points per square meter.

| Area covered [km2] | 1 | 6 | 10 |

| Flight velocity [m/s] | 5 | 10 | 15 |

| Flight altitude [m AGL] | 50 | 80 | 100 |

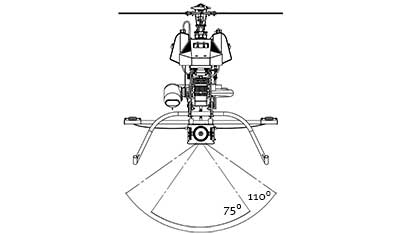

| Scanning angle [deg] | 75 | 110 | 110 |

| Point to point distance [cm] | 6 | 10 | 15 |

| Line to line distance [cm] | 6 | 10 | 15 |

| Points density [pts/m2] | 300 | 100 | 50 |

| Mission duration [min] | 60 | 60 | 60 |

| Data size [GB] | 8 | 12 | 12 |

| Photo overlay: | yes | no | no |

The laser scanner is mounted on the payload bay of the UAV helicopter. The wide scanning angle allows to fly on very low height over ground and scan vertical structures like walls or concrete dams in an optimal way. It is even possible to scan sideways.

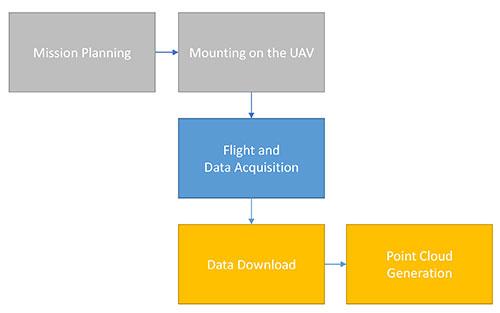

Workflow

1) Missionflightplanning and testing the laser scanner to get the desired point density. This can be done in the laboratory before going out to the flight field.

2) The payload is mounted to the UAV on the flight field within minutes. After the initialization process, (acquiring GPS, establish wireless connection etc.), it is ready for the scan flight.

3) The laser scanner can be started and stopped during the flight. Status information of the scanner and the INS/GPS system is sent continuously to the ground control station and differential GPS correction information is sent to the payload.

4) The laser scan data and the INS/GPS data is recorded and stored onboard. After landing, it can be downloaded to the ground control station laptop.

5) The RIEGL software package (www.riegl.com) is used to process the point cloud by combining laser scan data and INS/GPS position information data.